Technical Tuesday: Low Bore Axis

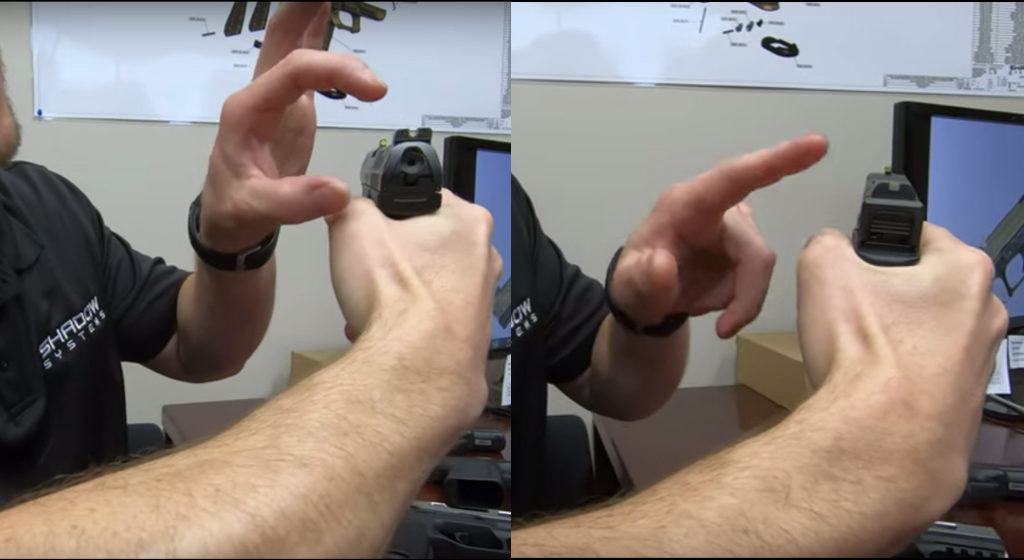

This week, we are looking at the bore axis of different polymer frames as it compares to the MR918 frame. One of the main pieces of feedback we are hearing from customers who have purchased the MR918 is how flat it shoots–what that means is there is not a lot of muzzle flip during firing. […]

Continue reading