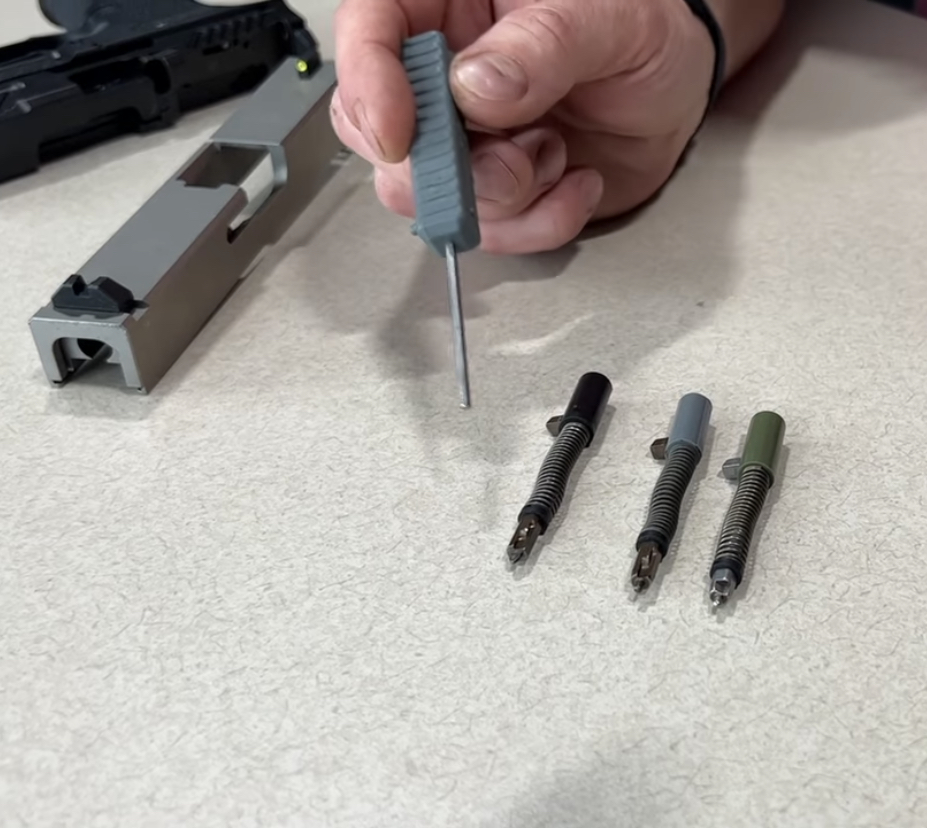

Technical Tuesday – How to Clean a Gun

Gun cleaning is a religious experience for some and a “never tried it before” for others. It should be a fast process that hits the areas that matter and focuses on reliability, not museum quality restoration. Here we do a quickie on how to clean a gun. Use what you’ve got. If you’re looking for […]

Continue reading