MR920: How to Mount your Optic (Optic Ready Slides ONLY)

This post is about how to install an optic onto the new patent pending optic cut featured on the MR920. For instructions for MR918 models, see this one.

MR920 Optic Mounting (Optic Ready Slides ONLY)

Overview: The patent pending Shadow Systems optic mounting system provides a low profile, high strength, multi-brand optic mount for your pistol. The system is unique in that it accomplishes this without the need for adapter plates or shortened screws.

The threaded holes in the slide fit corresponding holes on many optics in the market. If your optic fits in the recess in the slide and lines up with a set of holes, you can likely mount it on the pistol.

Preferred Mounting with Spacer (RMR, Holosun, Vortex Viper, Leupold DeltaPoint Pro):

For maximum strength, the system incorporates a high strength polymer compression spacer either in front of or behind the chosen optic. This spacer is not required to keep the optic affixed to the slide. However, it does add rigidity to the system and offers a buffering effect in extreme use/hard use environments. The spacers are sized specifically for certain, commonly selected optics. However, they may accommodate other brands which have a similar outer footprint.

The included spacers are designed specifically to fit the Trijicon RMR, Holosun with RMR-style footprint, Leupold DeltaPoint Pro, and Vortex Viper. Depending on the outer footprint of your chosen optic, the spacers may accommodate other optics as well. Check fit to determine if they will work for your optic if it is different from those listed above. You may also, in cases where a spacer is too large for the optic you have chosen, carefully modify the spacer with sandpaper to fit your optic.

The spacer is designed to be slightly oversized for the space that it occupies when the screws are tightened. By being slightly oversized, it remains under compression after the optic is mounted which removes all play in the system and creates a rock-solid mounting solution for your optic.

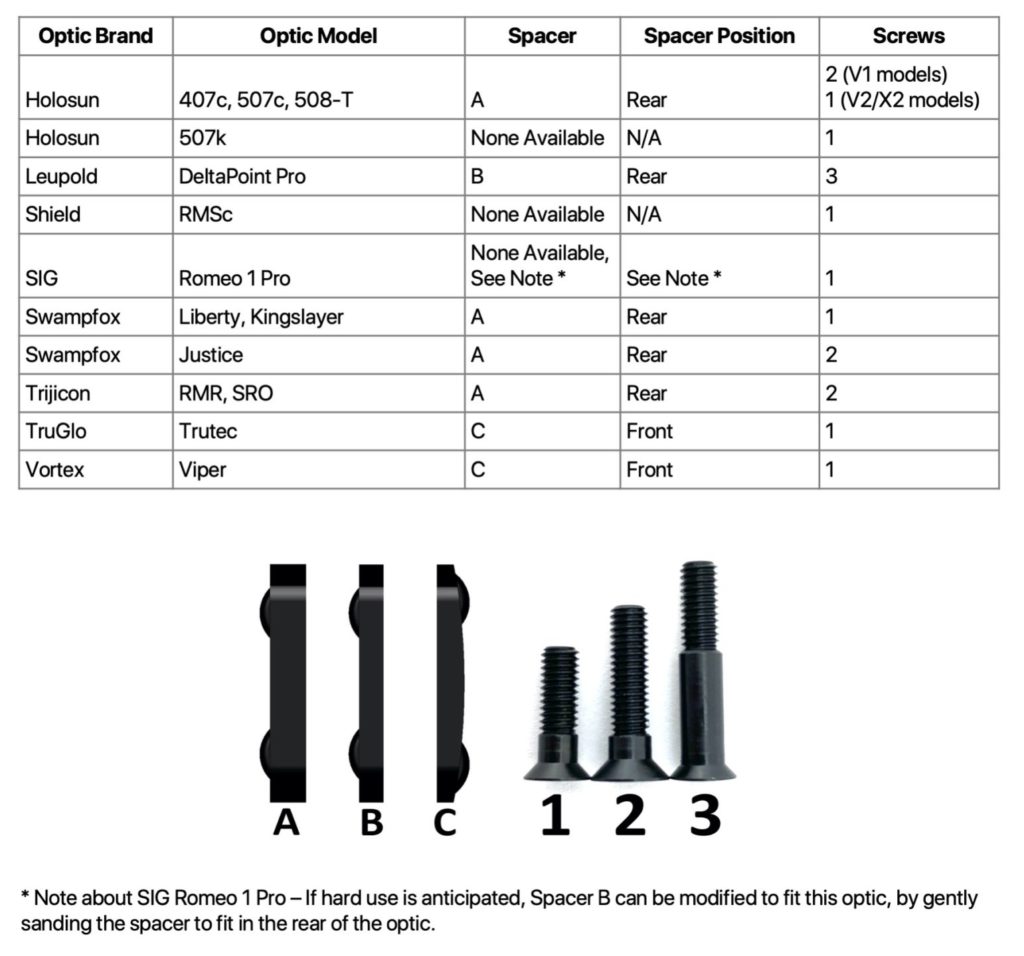

1. Refer to the table above to select the correct spacer and screws for your optic.

2. Install Spacer at the front or rear of the optic recess in the slide per the table.

3. Place the optic tight against your spacer and ensure screws are aligned over the holes in the slide. Note: You may notice the screws are slightly misaligned from front to rear. This creates the compression against the spacer when the screws are tightened.

4. Push the optic flat to the floor of the recess in the slide. Some optics will fit very tightly. You should be able to press the optic flat to the floor of the recess. If you cannot press the optic to the floor of the recess with firm finger pressure, call customer service at 469-458-6808 as your optic may be oversized and an extra step may be necessary.

5. Shake the included bottle of Loctite 243 for 20-30 seconds. Break off the tip and prepare your screws by applying a small bead to the threaded section of the screw only. DO NOT put Loctite in the holes in the slide as it can bind certain internal assemblies.

6.Carefully place your screws into the holes in the optic and thread them downward stopping before the screw reaches the optic. Before the smooth portion of the screw reaches the optic, place a large drop on the smooth portion of the screw.

7. Finish threading the screw into place and tighten to 10-20 inch pounds with a T-10 Torx tool. If you do not have a torque wrench and are using a typical hand tool, most people describe this as “very snug, but not excessively tight.”

8. If you applied the correct amount of Loctite to the smooth portion of the screw in step 6 above, you will have some “squeeze out” around the head of the screw once tightened. Carefully wipe this away with a Q-tip or rag. Be careful not to wipe Loctite onto the laser emitter that is normally at the rear of the optic body.

9. Allow the Loctite to cure for 24 hours before shooting. It is easily removable with hand pressure if needed for battery replacement, etc. You can store extra Loctite 243 by inserting a pin or nail in the end of the tube. It has a shelf life of about a year in most cases.

Mounting Without Spacer (Other brands):

If you do not have one of the optics listed above, but your optic fits in the recess in the slide and lines up with a set of holes, it can be mounted to the slide.

1. Experiment with the included screws to find a set that fits through your optic and can be fully tightened against the body of the optic (does not bottom out).

2. Follow steps 5-9 in the section above. Since you will not have the benefit of a spacer to help with alignment, as you tighten the screws, visually align the optic using the front or back of the optic recess as a visual reference. It does not need to be perfect, it is just a good idea to make sure it is not twisted to one side as sighting in will be easier.

Note on optics with windage and elevation locking screws on the rear: Some optics (Vortex Viper, TruGlo Tru-Tec, etc.) feature locking screws for windage and elevation adjustments that are located on the back of the optic. Since our system recesses the optic to achieve a low mounting position, these screws will not be accessible once the optic is mounted due to the position of the rear sight. To access the locking screws, you must drift the rear sight out of place. We are sorry for the inconvenience, but the only way around this would have been to eliminate the rear sight or mount the optic in an undesirable high position. We recommend drifting out the rear sight, following the mounting and zeroing procedures for your optic, tightening the windage and elevation locking screws (which are accessible with the rear sight removed), then reinstalling the rear sight.

Note on Co-Witness with Leupold DeltaPoint Pro: The Leupold DeltaPoint Pro has an extremely high body that prevents a co-witness even though we have deeply recessed the optic in the slide. We are sorry for the inconvenience, but the only way around this would have been to use extremely high sights which would have created an unacceptable co-witness with all of the other brands we fit. If you would like sights that co-witness with the DeltaPoint Pro, you may select aftermarket sights that are designed for a Glock-style dovetail. Be aware that you will want to choose a rear sight that is relatively thin from front to rear to prevent interference. For reference, the MR920 sight is 0.279” from front to rear.

I have the MR920 with the optic cut and am attempting to mount a Trijicon RMR. Is there a tool included with my MR920 to remove the screws for the optics plate that came mounted from the factory? …or do I need to purchase a tool, on my own, to remove these OEM screws?

It is a common T10 Torx bit that is needed to remove those screws. They can be found in stores such as Walmart, harbor freight, northern tool and the like.

Will either the Holosun HS407k or the HS407CO fit the MR920 Elite?

Yes, it will, using the #1 screws. However, there is not currently a spacer for that optic.

Luis and Richie are the best!!! I have a 920 an my guns shoots amazing!!!!

Just purchased your MR920L and I couldnt be happier. The pustol is amazing and it has now become my “Go To” carry piece.

Question: Will the upgraded holosun 508T v2 from the Holisun 507C fit my slide?

Hi Jerry, yes, it will fit.

Jessica, on the Holosun 508T V2, is it recommended to use the #1 screws as with the 507C V2?

Yes, that is correct.

Where can I find spacers? I didn’t receive any with my MR920 when I purchased it. Thanks

I’m sorry those parts were missing when you purchased it! Please email your address and serial number to support@shadowsystemscorp.com and my team will get those out to you. If you ever need additional replacements, they can be ordered here: Optic Mount Spacers

Does anyone know the thread type for the 7/16″optic mounting screws?

MR918=4/40

MR920=6/40

I have a MR920 Elite, I am replacing my RMR with a Holosun 507C. One of the screws is stripped and I need to replace it. It appears the same screw type is used for RMR & 507c,4-40 5/16?

You are out of stock, is screw specific for the Shadow Sytems? I cannot locate one anywhere.

Please email me your address to jessica@shadowsystemscorp.com and I will get a new screw sent out to you.

The new style Holosun 507c does not work with the #2 screws as specified. The #1 worked better. The #2 heads were too large to be screwed all the way into the counterbore of the optic. If compared to the supplied screws with the Holosun, the #1 screw head size is slightly smaller, but acceptable in size. The #2 however is larger and therefore will not work.

David, we did a Technical Tuesday video about this recently. Holosun changed the screw holes on the newest generation, so we now recommend using the screws the manual recommends for use with the Viper.

Just picked up my MR920, I’m stoked! I was considering fitting it with the new Holosun 509, however I was told the mounting is different. Can you confirm whether or not the 509 is compatible with the MR920? Thank you

The 509T can SOMETIMES be used with optic cover plate screws. It can be tightened, but the head will sit high. Some 509Ts will fit, some will not. We are working on different screws.

Pardon me ma’am…How can only “some” fit? That comment makes absolutely zero sense. It either fits or does not with the Mr920 and 509T. Being as this statement is coming from the manufacturer “maybe” or “sometimes” is quite confusing to the consumer. Please clarify, Thank you.

Dustin,

I understand your frustration–this is why we have NOT added the 509T to our approved optics list for our pistols. Of the 509T samples we have tested, SOME of them mounted with our optic cover plate screws and some samples did not–likely due to allowed variance at Holosun in the manufacturing of the optics. We are working on new screws for this optic, but until then, we cannot recommend this optic as not all of them will fit with the screws provided.

Has the Holosun 509T mounting issue with the MR920 been resolved?

It can bee mounted using the plate that ships with the optic and our cover plate screws.

Will this mount work with both SIG Romeo 1 Pro versions? SOR1P100 and SOR1P103?

Hi Daniel, The version that we have tested is SOR1P101. We have not tested the other versions.

Is there a solution which will allow mounting of the Vortex Venom to the MR920 Elite?

No, unfortunately the optic body will not fit. If you like Vortex brand optics, the Viper does fit the MR920.

The Vortex Venom can fit the MR920 with slight modification of the rear of the optic body with a Dremel tool. You need to shave off a small amount for it to fully line up with the MR920. I have it installed on mine and it worked with slight modification.

Jonathan bangash did you use any spacers with it after you modified it

Is it possible to mount an Aimpoint Acro to this slide?

No, sorry that optic will not fit.

Will a Sightmark mini spec 1 fit?

We have not tested that model. We cannot guarantee fit.

What are the issues with the ACRO on getting it to run with the mr920 slide? Just won’t fit the cut?

The ACRO requires a raised rail in the center of the cut similar to a pic rail. We have not worked out a modular solution for this yet but we are prototyping direct connect options.

Any solution to mount an Acro yet?

It should be released towards the end of this year–late fall is what I’m hearing.

How about a Trijicon RMRcc? Being that the mounting holes do not align, I am trying to determine what mounting plate to use. Any suggestions?

We do not currently have a solution for the RMRcc. We have heard that Trijicon is coming out with an adapter plate, however we have not yet tested that as an option.

They currently have adaptors for several different optics cut systems. Do you know if the adaptor plates that they currently have for other models will have holes which align with the MR920 mounting points? I am looking to put a RMRcc on this pistol if at all possible

To our knowledge, the RMRcc will not fit with the adapter plates currently in the market.

Will the AC32099 adapter plate fit the MR920? I bought a RMR cc thinking it would fit, but it does not fit the slide and the seller does not offer exchanges/returns on optics.

We have not tested that adapter plate and we are unaware of any plates that will work.

Anyone run swampfox liberty with their MR920? I used spacer A and the number 1 screws. The head of the screws slightly cover the battery cover. Anyone know of a fix to this?

I have the same problem. Have you resolved that issue?

Unfortunately, that is just the way our screws interface with the Swampfox. Some customers have experimented with turning the screw heads down a bit and had success with it, but it is not something we have tried.

Can the 920 optic cut slide be fired without the optic mounted?

Yes, absolutely! We also offer a cover plate if you’d prefer not to mount an optic at all–you can find those here.

I didn’t receive spacers with my MR920 and wanted to know where I can get spacers for my pistol. Thank you.

Please email me directly at jessica@shadowsystemscorp.com with your mailing address and I will get some out to you!

Anyone have success with Burris Fast Fire III? I have one on my AR and seems it would fit this pistol nicely. Just hate to loose zero on my rifle if it doesn’t fit. Thanks.

It does not fit.

Will this work with Romeo 1 footprint, and if so, which spacer?

The Romeo 1 Pro fits (only the pro model). There is not a spacer for this optic, but if you intend to have hard usage, you can modify Spacer B with a bit of sanding to fit.

Can a Romeo zero be fitted

Not to my knowledge. The Romeo 1 Pro can fit. Please see the most up to date chart here: https://shadowsystemscorp.com/mr920-how-to-mount-your-optic-optic-ready-slides-only/

Yes it can. There are pictures showing such.

Richie told me it’s possible to turn down the heads on the cover plate screws to fit the 509t. He said he could do it in a minute and a half. Do y’all have any plans to produce those screws? Thanks

David, There are plans to create a better screw option for the 509t in the future, though I do not currently have a release date for them.

The holosun 507k does not have a spacer for it will using it without a spacer cause issues?

The mount may not be quite as rigid without a spacer. Our screw length is such that the optic should be perfectly fine for normal use, but if you are quite rough on your equipment, we would recommend choosing a different optic that does have a spacer from the chart in this article.

Can you guys release a file to 3d print a spacer for the 507k, (rear mostly, front too even… y’all know the dimensions and engineering tolerances… I’d be happy to test any demo prints 😉

I agree, I see a lot of posts regarding wanting an optic that has no overhang, and releasing an option or spacers to clear the difference would be a great thing.

Did you use a mounting plate, like the one by cwhs or did you mount it directly to the slide? Love the idea of using a 507K for its footprint, how do you like it so far

I have an RMR type 2 that I plan to use but there is a note form Trijicon to the effect, if you want to use it on Glock MOS you should also use the Trijicon mounting plate to assure water resistance. Is the optics cut on the mr920 the same as a Glock MOS? Should I use the mounting plate?

Tim, we do recommend using a battery sealing plate to protect the RMR from moisture, since the optic does not have a closed body. Here is the one that fits our optic cut.

Hi I’m trying to mount a HS 507c V2 on my MR920 Elite. The pre drilled hole on the right accepts screws just fine, but the one on the left makes the screw stop 1/3 way. It won’t budge or go any deeper. I think the threads may be messed up, the one the right goes in all the way with a hand T10 torx tool. The one on the left is impossible to get any deeper. How can I fix this?

Hi Anish, could you please take a photo of the screw hole causing problems? Preferably with flash? Please send that photo to our tech team at support@shadowsystemscorp.com

You could use a bottoming tap to clean (chase) the bottom threads.

What is the best optic recommended to run the best on the mr920 all around is what I’m asking I guess

It really depends on personal preference. The gold standard has historically been the Trijicon RMR, so you can’t really go wrong there. For a great value, Holosun optics are the choice. See the chart in this article for the optics that we have tested and approve.

I just bought a shadow system mr920 and i have a holosun 507k x2 from my 43x mos. Will i be able to use it on my mr920?

507K can be mounted using screws and supplied retaining compound. It does not have a spacer, however.

Hi Jessica! Is there any plans to develop a spacer for the 507k? Thank you in advance and also for your excellent customer service by answering all these questions in the comment section.

We do not have that spacer in development at this moment.

I purchased a shadow 920 combat which is all they had then realized that a Elite would have been better since it is optics ready.

please direct me to a link to your website where I can purchase a slide to change out the ones I have on my combat or what would my options to be to mount optics on my mr920 combat.

Hi Ima, I am sorry to report that we do not sell slide separately, and we cannot add the optics cut after production. Unfortunately, for folks who choose to purchase the non-optic-ready versions of our pistols, we do not have a good option to mount an optic.

On that sad note, just about any competent machinist can mill the slide and thread the holes for you. Moat charge 150/200 usd for the service.

There are many specialty shops that perform the machining for handguns exclusively.

Will the Holosun 507C-X2 fit my DR920 Elite?

Yes it will! Please use the screws recommended in the chart in this article above.

What’s the issue with mounting the Aimpoint Acro with the standard RMR adapter plate? A side by side photo of the Acro mounting plate next to a 509t plate shows that the Acro plate is longer; is it too long to fit the slide cut on the MR920? If that’s the case, could the plate be trimmed to fit the slide cut?

The Acro is too long for our optic cut.

This is not an optics question….so please forgive me. I am looking for a compensator for the DR920. Can you hive me some suggestions?

The one we hear the most positive things about is Herrington Arms.

Regarding mounting the 509t- is the issue that the bolts are too long in some cases? If that’s the case, I can easily file a thread off in my garage.

Or is the issue that the heads of the screws don’t sink deep enough into the countersunk holes? That, too could be easily alleviated.

I’m seeing talk of revised screws for the 509t- at some point will those be available for purchase for those of us who already have purchased a gun?

Thanks

Tom, the 509t can be mounted with the plate that ships with the optic and our coverplate screws.

Really happy with my MR920 Elite . Any word on FIT, ADAPTER PLATES or a SLIDE CUSTOMIZED for the Trijicon RMRcc ? Thank You …….

We do not currently have a solution for that optic.

Hello Shadow Systems,

Do you have an update to the 509T Screws. I have 2 509Ts that I’d like to mount on our DR920 COMBAT and MR920 Elite.

It will mount with the plate that ships with the optic and our cover plate screws.

Trijicon rmrcc, will it for the mr920

No.

Hello, do the sights co-witness with the SigRomeo 1 Pro?

Yes, you will get a lower 1/3 cowitness.

The #1 screws are in the way of the battery cover as I mounted the swampfox liberty. Is it OK to use the screws that came with the optic?

Unfortunately, that is just the way our screws interface with the Swampfox. Some customers have experimented with turning the screw heads down a bit and had success with it, but it is not something we have tried. Do not use the screws that came with thee optic as they could damage your slide.

Will the Holosun HE507C-GR-V2 fit the MR920L? If so what spacer and screw?

Yes. Use the number 1 screws and spacer A in the rear position.

Does the shield RMS not the RMSC fit? Also the 507/407 is one of the best looking optics on your firearm with no side overhang. I don’t understand why not make a spacer for it after all this time. If you guys list an optic as fitting then a spacer would be great to fill that gap in. What other optics fit with no side overhang and can fill the gap or utilize a spacer?

Quick question. Sorry if I missed the answer anywhere. Holosun 507k is on the chart…would the Holosun 507k xs be the same compatabilty? Mr920 Combat w/ Optic cut.

Sorry Holosun 507k X2 is the number.. upc 810047071211

Yes, you will want to use the number 1 screws.

So I’m confused. I asked the same question 6 days prior and you said there wasn’t a spacer available? So does or does not the 507k fit? Perhaps I should’ve specified the 507k X2?

There is not a spacer available, nor one in production, for the 507k. The optic will fit, though the mount may not be quite as strong for hard use, since it will be installed without a spacer.

What screws hold the cover plate “firmly” in place? I’ve tried every screw that I have in box of my MR920 (bought it used) and the cover shakes with the shortest ones in there.

Mounting Screws: New Generation Optic Cut

Choose “Cover Plate Screws” from the drop down menu.

I’m wondering why you guys would advertise the cutout fits Shield rds’s and not offer some kind of spacers for it. I really, really like the weapon but I don’t like that I’m not going to get a snug fit with the optic I want to use. Are there plans to produce larger spacers to accommodate these small rds systems?

The spacer does provide some additional stability for the optic, however, the screws our optic cut uses are so much longer than any other optic cut in the industry, that even without the spacer you will have a stronger mount of the optic to slide than with any other pistol out there. Yes, for extremely hard daily duty use, we do recommend selecting an optic that has a spacer, but you should be perfectly fine to run the RDS without one. We do not currently have a spacer planned for that optic at this time.

Will the new Steiner MPS fit the 920 optic cut?

We are currently testing mounting options. We just received an MPS to test today. We should be able to answer that question soon!

Will the Bushnell RXS-250 fit the MR920 optic cut?

We have not tested that optic, so cannot yet say. If to has an RMR footprint, there is a chance that it would fit.

Will the MPS only fit on the limited edition XR920 Acro cut or is there a way to mount it in the original optic cut like the 509t?

David, you can buy an Acre Primary Machine RMR adapter, but you will need to buy your own custom screws to fit. Please contact my Technical Team at support@shadowsystemscorp.com if you would like additional details if going down that path.

My optic plate cover screw heads are too large to mount the plate for my 509t. Do y’all have updated cover plate screws I can buy? Or do I need to modify mine?

They’ll need to be modified.

I have a modified C-more STS2 that fits the slide but needs cap head screws. What is the correct screw size and thread count?

6-40 screws

Where can I find a dimensional footprint of the optic cut, I’m trying to 3d print the spacer for a 507k, and need to find an image that shows a top down view of the optic cut with dimensions showing screw holes. Any response would be greatly appreciated. I know you don’t make the spacers and have no plan to make the spacers for the 507k so I am making them on my own. Thank you in advance

Hi Mr. West, is the email address you used for this comment a good one to use? I will get you the file you need and email it directly. If you’d prefer I use a different email address, please let me know either here or by emailing me directly– jessica@shadowsystemscorp.com

Any idea on what height sights are needed for a lower co-witness with a Delta Point Pro? Will regular suppressor height sights work or do they need to be taller than that?

Suppressor height sight should cowitness with the DPP

Is there a spacer for a 507k use d on a mr920 yet?

There is not yet.

Will the Holosun SCS fit? Thanks.

The SCS will not fit, but the EPS will.

Which screws and spacers will fit the holosun eps on the mr920?

We have not yet tested thew EPS on the MR920. It should use the RMR spacer, but we have not yet confirmed which screws. Please feel free to play around with your mounting screws to see what works, you can’t hurt it if you’re using our optic screws.

Forgive me if I don’t much about guns but I’ve been searching for days and I can’t find an answer. I’ve recently bought my MR920 from a retail store a couple weeks ago and I wanted an optic on it. So I went ahead and bought the 508T V2 but I realized my slide may not be “optic ready.” I would like to know my options here. Can I buy a slide that’s optic ready from Shadow Systems? Is there anywhere I can get one or replace It with my current one? Can I even do that? Is there a plate or adapter I can use? Is there anyone who can make the necessary adjustments on my slide to make it optic ready? Do you mean to tell me there is absolutely no possible way I can put my optic on my MR920? I really like my MR920 but It would be a shame if I can’t put my optic on it. I just want to know all my options because I’ve spend countless hours each day trying to find information and I find little to nothing. Thanks in advance!

Hi Will,

Unfortunately, I don’t have good news for you. If you want to mount an optic on our pistols, we really suggest that you purchase a pistol that is optic ready. We cannot add the optic cut after production and we do not sell slides separately. The only option for you at this point, if you are quite sure you must have an optic on your MR920, is to have someone reputable add an optic cut for you, however this is not something we can recommend as there are many folks doing poor work of this. We also cannot warranty function of the slide after such work is done to your pistol. I know that’s not what you were hoping to hear. Sorry to be the messenger.

Just purchased an XR920 Elite. I was curious about the Holosun 509 ACSS fom Primary Arms. It comes in two models. One comes with a MOS mounting plate, and the other comes with a 507C mounting plate. Will either of these work? I’ve come across conflicting and confusing info. Thanks.

The Holosun 509T is mostly compatible with our optic cut. It can usually be mounted using the Holosun adapter plate included with the 509T and our optic cover plate screws. The screws will sometimes sit slightly proud of the adapter plate, and so they may contact the underside of the optic. This will cause superficial wear with regular use.

In some rare cases, due to manufacturing variances in the Holosun adapter plates, the adapter plate and cover plate screw combination may not provide sufficient clearance to allow the 509T to mount. If this is the case, you might need to modify the diameter of the screw’s head for correct fitment. We also had great luck using aftermarket screws to successfully mount the adapter plate. We used 6-40×15/32″ screws from Brownells. The part number is 228049. The link will be posted below:

Screws Link: [https://www.brownells.com/gunsmith-tools-supplies/small-hardware/metal-screws/6-40×15-32-t-10-weaver-oval-screws-12-pack-sku080924364-41830-3582.aspx?sku=080-924-364](https://www.brownells.com/gunsmith-tools-supplies/small-hardware/metal-screws/6-40×15-32-t-10-weaver-oval-screws-12-pack-sku080924364-41830-3582.aspx?sku=080-924-364)

Part Number: 228049

I am mounting the Holosun 507c x2 to my DR920 Elite, the guide lists spacer A and the #1 screws. The two #1 screws are slightly different, by approximately 1 millimeter; is this going to impact the handguns operation or should I not be concerned?

Tom, please email my team to get some new screws: support@shadowsystemscorp.com

Does the HOLOSUN Technologies HS507C-X2 fit and if so which hardware do I need to use?

Yes, it does. Please see the chart in this blog post to show you what screws and spacer to use.

Saw earlier on this thread that Shadow Systems received the Steiner MPS. Any update on the fitment on 920 models? I have the DR920P.

The MPS does not fit our regular optic cut. It can be installed only on the pistols that we have run with a cut for the Acro. Those have not yet been released.

I just purchased a XR920 to replace my Staccato P for duty. I want to run a Delta Point Pro and per my agency SOP…I have to co-witness with irons. What sights (height) will I need need in order to do this? Will running taller sights hinder my holster selection?

For a co-witness with the DPP, you will need the Ameriglo 5xl suppressor sights.

Will there be a spacer for the holosun eps and eps carry?

On the CR920, yes.

To clarify, spacers for the Holosun EPS will ONLY be available for the CR920? There will be no EPS spacers for the full size models i.e. DR920. This optic will have to be mounted on a full size model without the support of a mounting spacer.

Yes, that is correct. The EPS has a spacer on the cut for the CR920, but there is not a spacer to fit that footprint on the larger guns. It can be mounted to the larger pistols using the screws included, but there will not be a spacer. The mount will still be stronger than most other optic cuts in the market, but will not the the insanely rock solid mount you are used to on your Shadow pistols.

Why no spacer for the MR920. This is still a gun a lot of people conceal and I am looking at either an EPS or EPS carry for my new personal carry as i use to carry a G19.

Here it is! https://shadowsystemscorp.com/product/mr-dr-xr-eps-k-spacer-kit/

What is the thread pitch for the forward holes on the DR920? I stripped one mounting my Holosun HE508T-RD X2 and cant figure out a replacement.

You can get new screws here.

I am really hoping someone will get back to me. I’ve left 2 voice messages and an email. Got the reply someone will look into this and get back to you return email. I bought two MR920Ls from Liberty Chest that were shipped to my dealer. One of the two was missing the packet taped to the box lid with all the screws, spacers and loctite. Need one of those so I can mount the optic please.

A follow up question about the optic spacers. I was under the impression from your video and description that the spacer and the optic would be a snug interference fit in the cut out. Checking both 920L’s and with both Holosun 508T’s and just the one spacer A there is a very loose fit in the cutout. Is that normal and will it keep the optic from moving should or when the optic gets wacked?

Hi, I have a mr918 and purchased the spacer as well as all needed screws. My optic did not come with a bottom cover and the battery is exposed. Do I need to purchase a base plate from trijicon? Or do I just place the optic directly to the slide? (worried about water damage). Thanks

We do recommend a sealing plate to protect from water damage. You can find one here.

I strongly encourage you to update the table of optics/spacers/screws with info on optics not listed. Jessica has done a great job of providing info on other optics in her responses here, but a person has to wade through all the comments to find that info.

I’d even list the popular optics that you know don’t fit. This will save you time because we won’t have to keep answering the same “will it fit” questions repeatedly. It will also reduce the frequency of customers purchasing an optic and then finding out it doesn’t mount to their pistol.

Jeff, Thanks so much for the feedback! The optics we have included in the chart are the ones that we have a full mounting procedure for, using the screws and spacers included with your pistol. Yes, there are other optics that do fit, usually with some finagling, but these are the ones our team has approved for long-term hard use and can therefore recommend. As additional optics get added to that “recommended” list, this chart is updated. If it isn’t on the chart, then it is not a recommended optic for our system at this time.

I’m having trouble getting my vortex venom to mount on my DR920. The rear cut is slightly too flat to receive the optic as is with or without a spacer up front. Otherwise the pistol is fantastic and I could only barely be happier with it.

Hi Zach, The Vortex Venom does not fit our optic cut. The Vortex Viper does. You can find the most up to date charts for what optics fit here.

I was just gifted an MR290 from my team leader, for my 10th Alive Day, that was with me the day I stepped on an IED. A couple of things, I’m guessing these mounts are in the original case the MR920 came in and also, the extended magwell is missing the screw that locks it on to the base of the grip, is there any way I can older just that small piece? Thanks for the help!

Hi Corey,

I’m sorry that part was missing. Please email support@shadowsystemscorp.com with your mailing address and serial number and we will ship that part out to you.

Can you recommend a screw for mounting a swamp fox justice? The ones I ordered, the head is too big and covers a portion of the battery compartment.

That is the only fitment for the Swampfox Justice.

Hi, is the DR920 fit the Aim point ACRO Get 2 ?Does it need Special Plate and spacer? Thanks

The ACRO can be mounted with the Primary Machine RMR to ACRO adapter (0.150).

Considering options…Can I mount this on my CR 920 Elite? Holosun (HE507C-GR-X2-ACSS)?

Is this chart also for the CR920? Or where can I find a chart. Thanks

https://shadowsystemscorp.com/opticcut/

Any update on the spacer for the holosun EPS on the MR/XR/DR platforms?

The EPS is a much more appealing option then other red dots given it’s fully enclosed and sit much lower then other enclosed red dots.

Is it safe to direct mount the EPS on the mr920 without spacers?

Here you go!! https://shadowsystemscorp.com/product/mr-dr-xr-eps-k-spacer-kit/

Hi Jessica, thanks for reply my last question so quick. Instead of ACRO, I just got SRO on my DR920 Elite for competitions mainly. But I found the descriptions “Not recommended for SRO ‘course easy scratch the glass” on the main website. Is it mostly because the ejected shell? Or general usage like holstering ,etc in the reports? Would you tell me some, thanks

Does anyone know what needs to be done, in order to mount a Eotech Eflx?

Something must have changed because I just used the SG9S-00-54A spacer to mount a Holosun HE507K GR X2 (front spacer) to my CR920X. There was no need for a rear spacer and the front spacer fit perfectly, and even gave a little bit of tension as is desirable. The comments stating that this spacer doesn’t fit the Holosun 507 series may be old information. I’m posting this on 11/2/2024.