Technical Tuesday: Compensators and cone of fire

Technical Tuesday: HS923 at the Range

Technical Tuesday: Confirming function with carry ammo

Technical Tuesday: Recoil Control

Shadow Systems Takes on the Suppressor Market with New HS923

Plano, TX (January, 2024) – This week at SHOT Show 2024, Shadow Systems is entering all new territory with its Suppressor, the HS923. Optimized for 9mm pistols with threaded barrels (1/2 x 28 pitch), the HS923 is a lightweight, modular option for highly effective sound suppression. “We wanted three things: the ability to prioritize suppression […]

Continue readingShadow Systems Releases Two New Compensated Pistols for SHOT Show 2024

Plano, TX (January, 2024) – Following the success of the compensated full size DR920P and subcompact CR920P, Shadow Systems has announced the release of two new 9mm pistol models that feature an integrated compensator. The compact MR920P and crossover sized XR920P are being released to the public at the 2024 SHOT Show convention in Las […]

Continue readingTechnical Tuesday: Shadow Systems Gen 3 Slide

Shadow recently released a slide for the Gen3 G19 platform. This product includes the best features that you have come to know from Shadow, particularly our optic cut. We discuss the slide in detail in this video, including the included extras that others don’t offer.

Continue readingTechnical Tuesday: Aftermarket Trigger Issues

We are tinkerers too! But tinkering often goes wrong with triggers, and we do an overview here of one flavor of mechanical failure we have seen often.

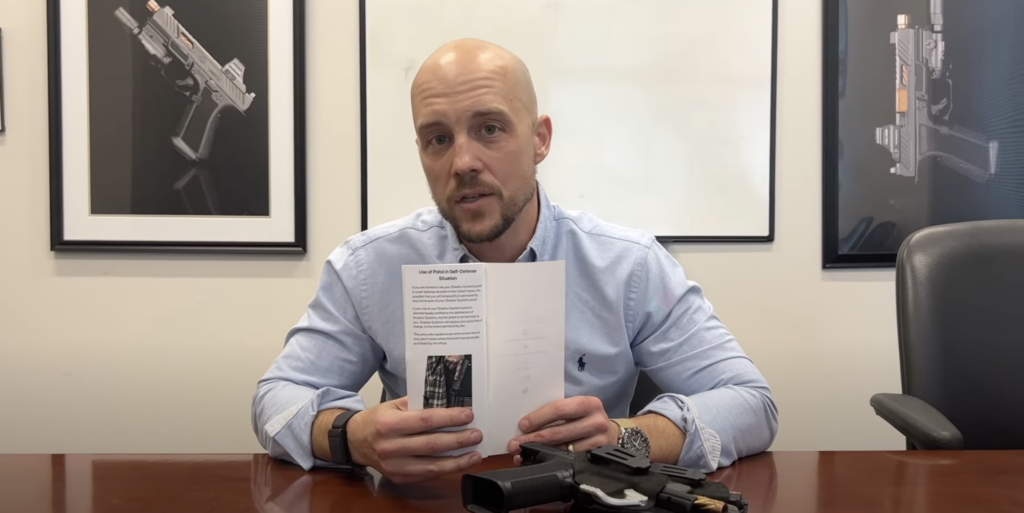

Continue readingTechnical Tuesday: Shadow Systems Self-Defense Warranty

Since the beginning, Shadow Systems has offered a unique warranty that protects our customers when the worst happens. Here we discuss the program and how it is applied in self-defense cases.

Continue reading