We work hard to get orders out as quickly as possible, but our demand does fluctuate. Please allow 2-10 business days for parts orders; see pistol product pages for latest information on pistol lead time.

We currently accept payment from all major credit card / debit card companies. Payment is taken at the time of your order and authorization must be approved before we can deliver your order. All pricing is listed in and all payments are received in US Dollars.

We also offer gift cards for those who can’t decide what to get their favorite shooter.

Customer is responsible for all shipping and freight charges.

We wish we could control the carriers, but sometimes they miss their deadlines. We will not be responsible for shipping delays caused by any carrier.

Shipping times are based on time in transit and do not include time for fulfillment or lead times. An estimated lead time is available on the pistol product pages. Selecting Expedited Shipping will not affect the fulfillment lead time required for your pistol order.

Shipping rates are calculated based on weight, destination, and shipping service. Your final shipping and handling amount will be displayed before your place your order

You must notify us at time of purchase if a signature is required for residential deliveries. We are not liable for any lost or stolen goods that are delivered to a residence without requiring a signature.

** Due to the current high volume of orders, we are unable to change orders that are already in process. If you have ordered the incorrect part, please call us at 469.458.6808 to cancel your order before it is shipped.

** For Law Enforcement magazine orders in restricted states, please reach out to your local dealer so they may order these magazines from distribution.

** Once your order has been processed it cannot be canceled. Since items tend to sell out quickly, we recommend immediately placing an order for the replacement merchandise. We are unable to reinstate an order once it has been canceled. You may place a new order, subject to our current availability and pricing.

We want you to feel completely satisfied with your purchase. If you are not satisfied for any reason, you may return an unused item within 30 days from the original date of purchase. Items that are being returned must be in new and unused condition. If a return is required after 30 days, a 15% restocking fee will apply. After 60 days, we will not be able to accept your return. Please make sure the items you wish to return meet these criteria prior to initiating a return. All product returns require a Return Authorization Number. Refunds do not apply to the cost of shipping or handling charges. The customer is responsible for the actual price of shipping even if the shipping was free or discounted. In some cases, the actual price of shipping may exceed the amount originally charged for shipping, the difference in shipping cost will be deducted from any refund. Refunds are applied to the payment method used at the time of purchase. Once we receive your package, please allow 5-10 days for us to inspect, approve, and process the return. A Return Authorization expires 30 days from the date of issue. Expired Return Authorizations or returns without a Return Authorization will be subject to a 15% restocking fee.

If you refuse delivery, a credit will be issued for the price of the merchandise minus the actual cost of shipping and the cost of return shipping. All credits will be applied to the original payment method.

OFFICIALLY: Five Year Limited Warranty

Shadow Systems products are guaranteed to be free of defects in materials and workmanship that adversely affect operation for a period of 5 years from the date of original purchase. If there is a problem with your product, we will take care of it, just give us a call. No need to fill out a warranty card, keep the original receipt, or sign an affidavit. This warranty is fully transferable. The warranty does not cover loss, theft, deliberate damage, or cosmetic damage that does not affect function.

HOWEVER: If you EVER have a problem, give us a ring and we’ll do our best to get you squared away. 469.458.6808

The break-in period for the Shadow Systems pistol is 150-200 rounds. The pistol has close tolerances and benefits from a “wearing-in” period before reliability and performance are at their best. During this break-in period, the parts will fully mate and springs will achieve their final set. Keep the pistol well-lubricated during this period.

The most commonly lost parts are available for sale at the links below:

You can find other small parts here.

If you do not see the part or accessory that you are missing at the links above, please call 469.458.6808 or email support@shadowsystemscorp.com.

Use only the highest quality factory ammunition. Your pistol is designed for use with +P ammunition, but do not use ammunition marketed as +P+ as there is no SAAMI designation for +P+. Budget priced and/or reloaded ammunition can suffer from quality control issues and result in degraded performance and reliability. If you are trying to achieve maximum accuracy, it is beneficial to test different types of ammunition (manufacturer, bullet weight, etc.) as your Shadow Systems pistol may prefer some loads over others.

The following optic brands have been tested in the MR920’s patent pending multi-footprint optic mounting system:

There are likely other brands and optics that will fit and function well on the MR920. As our team continues to test, more optics will be added to this list.

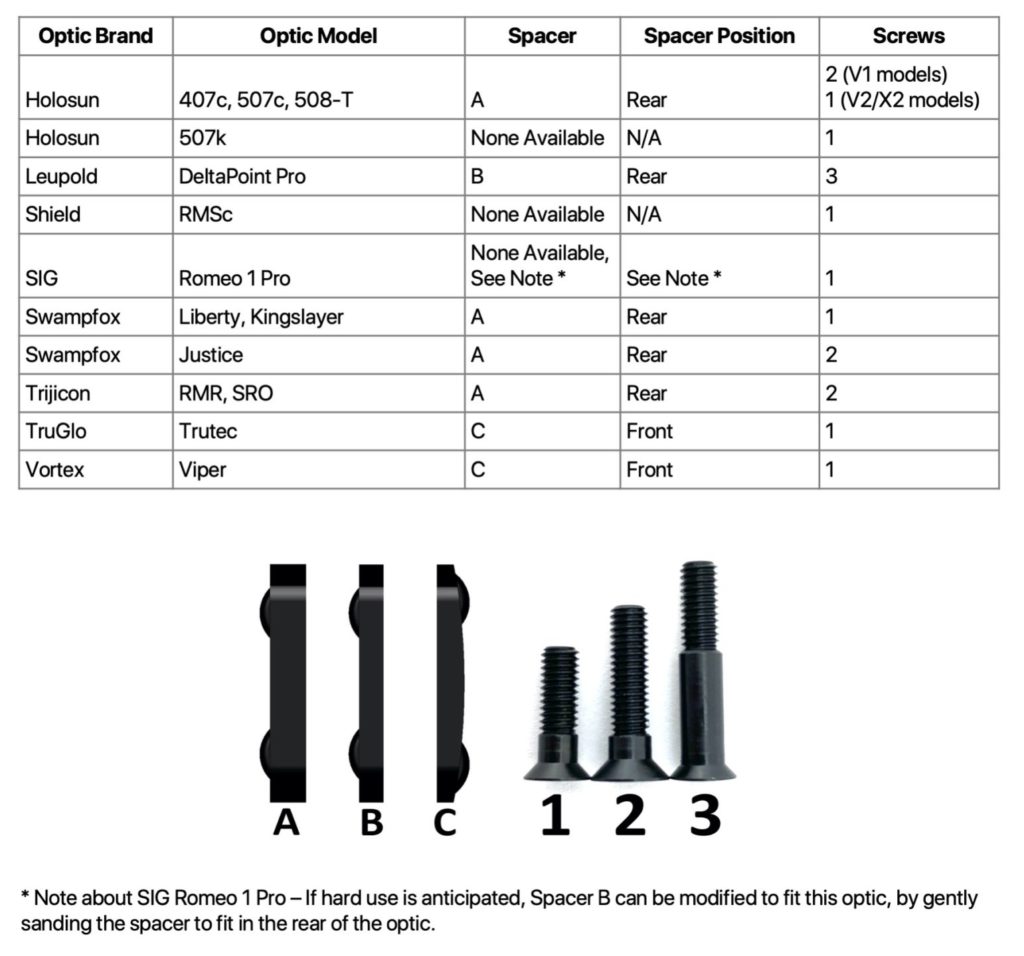

Below is the chart for how to install each of the above optics using the screws and spacers included with your MR920:

The MR918 optic cut can only accommodate optics with the RMR footprint, including: Trijicon RMR & SRO, Holosun 507c & 508t.

Our pistols are designed to fit and function perfectly with standard holsters designed for the Glock platform of handguns.

We did this since holsters fitting the Glock operating system are plentiful in the market, and frequently our customers already have one. That means customers have lots of off-the-shelf options and may already own a holster that fits! As far as Generations go, our pistol is modeled on the Gen 4 operating system so go with that choice if its applicable.

The MR920 and XR920 is compatible with G19 holsters, the MR920L and DR920 pistols are compatible with G17 holsters. A Gen 4 holster will give you the best fit.

The CR920 is designed to fit and function with standard holsters designed for the Glock 43x MOS. If you can not find a listing that states “CR920”, make sure that you find a holster that fits a Glock 43x MOS. The list below will continue to grow as we are also currently testing additional holsters made by other manufacturers.

There are an enormous number of holster manufacturers and models out there so we cannot confirm that every single one will fit. Every so often, a customer reports that their holster does not fit their Shadow Systems pistol. However, these cases are extremely rare. In our experience, holsters made by the following companies will fit our pistols without issue:

Light-Bearing Holsters:

First, if you lost your screws, they are available for sale on the website here.

Our optic system is likely different from other systems you have used in the past. WE CANNOT EMPHASIZE ENOUGH THE IMPORTANCE OF FOLLOWING THE INSTRUCTIONS IN THE MANUAL. Failure to do this can result in a weak/insufficient mounting and/or damage. The instructions are detailed with pictures to walk you through the process. Be patient and do it right the first time. You can view the manual instructions here.

The system is designed to work with Leupold Deltapoint Pro, RMR-style footprints (Trijicon RMR, Holosun, etc.), and other optics using a more narrow screw pattern such as Vortex Viper, TruGlo True-tec, Sheild RMS, etc.

As an aside, there are some optics that have the same screw placement but do not fit because they are excessively long from front to rear. Examples would be the Burris FastFire and Vortex Venom. If you aren’t sure, call 469.458.6808 or email us at support@shadowsystemscorp.com.

We include three sets of screws, spacers, and the correct Loctite to use with our system. The Loctite we include is the only approved threadlocker/retaining compound for this system. Use of other Loctite compounds, or other similar products, may not have the desired effect including being to thin and running into the internals causing key components to bind.

First, if you lost your screws, we have them available for sale here.

For our legacy MR918 slides, there are three lengths of screws related to our RMR cut slides.

1. Optic Mounting:

2. Cover Plate Mounting: We ship 1/4 inch screws for mounting our cover plates. The longer optic mounting screws will “bottom-out” before making contact with the cover plate and will not work.

Any time you add something to a pistol, particularly something as heavy as a suppressor, the dynamics of the system change. We have designed our pistols to function in the vast majority of situations, but with so many possible combinations of ammunition and suppressor out there, reliability issues can and do happen.

If you are having issues, start by making sure that your piston in the can is clean and operational (a common problem pointed out to us by tech service at SilencerCo) and that the can is fully threaded onto the barrel. Next, we know this sounds obvious, but without a spring change your suppressor is far more likely to work with full power ammunition.

If issues persist, you must assess the cause of the failure and appropriate corrective action. Generally, the change will be related to the recoil spring assembly:

Again, all of this assumes that you are using high quality factory ammunition and that you have not otherwise modified your Shadow Systems pistol.

We are fortunate to live in a time when there are many good firearm finishes exhibiting excellent corrosion and wear resistance. We offer two primary finishes:

Titanium CarboNitride (TiCN) a.k.a. “Bronze TiN”: You may have seen gold colored Titanium Nitride (TiN) before in the firearms industry. We have used it extensively in the past and it is a very good finish that has become quite popular. However, we have seen such an improvement with bronze Titanium CarboNitride (TiCN) that we now use it as our go-to barrel finish. TiCN is basically gold TiN’s lesser known, tougher cousin. TiCN is very hard and offers superior corrosion resistance and lubricity. We like the fact that it looks great, but it was originally chosen for its material properties. This finish is used frequently in industrial settings, in particular, on cutting tools used on very abrasive materials.

Nitride: Shadow now uses Nitride to finish our black components. There are many recipes and names for nitride (Tenifer, Melonite, QP, QPQ, etc. are all the same or similar). Generally, they all mean a treatment that makes the part super hard at the surface followed by a rust preventative blackening treatment. We used to use DLC and while we liked it, we did see more finish wear in high contact areas. We also found that nitride did better than DLC when the gun was run hard and/or run dry. We now use nitride exclusively.

Yes, we know guns were reliable and accurate before people machined flutes on them! However, there are enough advantages to fluted barrels that we have incorporated them into the design.

Probably the most important impact is that they give debris a place to go when your slide is cycling, enhancing reliability. They also tend to “hold” lubricant, keeping your slide lubricated a little longer and distributing it evenly. Lesser impacts include: better barrel rigidity, better cooling, and weight reduction.

Our pistols ship with a spring that is optimized to function with a wide range of ammunition while properly protecting the frame from damage. We use chrome silicon springs which have a longer service life than conventional springs, especially when they get very hot. We recommend replacement about every 5K rounds.

Unless you are using an exceptionally light target load, lots of something really nasty and powerful, or a suppressor, you will likely never need to change your spring weight. Using a light weight spring is not advisable with full power ammunition (excepting the specific case involving a suppressor) because it tends to increase wear and tear on the gun. Keep the springs on the heavier side when in doubt, but our standard spring tends to balance all these considerations fairly well.

Shadow Systems Pistols have been approved for the following competition associations and divisions:

MR918 (all models) is approved for use in USPSA Production, USPSA Carry Optics, IDPA Stock Service Pistol, IDPA Carry Optic

MR920 (all models) is approved for use in USPSA Production, USPSA Carry Optics, IDPA Stock Service Pistol, IDPA Carry Optic

MR920L (all models) is approved for use in USPSA Production, USPSA Carry Optics, IDPA Stock Service Pistol, IDPA Carry Optic

DR920 (all models) is approved for use in USPSA Production, USPSA Carry Optics, IDPA Stock Service Pistol, IDPA Carry Optic

You can check your balance on an existing gift card here:

The sale, transfer, transportation, or shipment outside of the U.S. of many of our products is prohibited or restricted for export without complying with U.S. export control laws and regulations. Violations of these export laws are subject to severe criminal penalties. The purchaser and recipient of any of our items must recognize their legal obligation to abide by all laws in regards to the international Traffic in Arms Regulations (ITAR) and the U.S. Export Administration Regulations (EAR). If you wish to purchase an item for ultimate shipment or use outside of the United States make sure to check our dealers for one of our international partners. Please contact us if you have questions or require additional assistance.

For questions about FFL Transactions contact support@shadowsystemscorp.com. If you need to look up a local FFL for shipping, please click here.

On occasion, Shadow Systems runs giveaways of product and prizes on our website, social media, or at in-person events. These giveaways are hosted by Shadow Systems and are in no way affiliated with any social media service or platform.

Giveaway and contest rules: