Our slides are machined from heat treated 17-4 stainless steel which is generally regarded as the perfect material for hard-use firearms components. In addition to high mechanical strength, 17-4 is corrosion resistant and can be heat treated to optimal hardness levels. 17-4 is more costly and difficult to machine than 416 and 4000-series carbon (used on most production gun slides), but it’s the best stuff for the job.

Our slides are machined from heat treated 17-4 stainless steel which is generally regarded as the perfect material for hard-use firearms components. In addition to high mechanical strength, 17-4 is corrosion resistant and can be heat treated to optimal hardness levels. 17-4 is more costly and difficult to machine than 416 and 4000-series carbon (used on most production gun slides), but it’s the best stuff for the job.

We machine our barrels from 416R stainless which is regarded as optimal for barrel steel. In general, stainless is better than carbon steel for barrels as it resists the heat and abrasion of the firing process and should show less wear over the life of the barrel. Within the stainless steel family, there are other barrels made of 410 and 416 which do well, but 416R has less suphur content. This factor, combined with other properties of 416R, allow it to resist fracture at extremely cold temperatures. Again, this makes it ideal for a hard-use firearm component. In case you were wondering, 17-4 (great stuff for slides) is very time consuming and difficult to machine in a barrel format. It is also “overkill” for the job. 416R is proven in this role and is more appropriate for barrels.

We are fortunate to live in a time when there are many good firearm finishes exhibiting excellent corrosion and wear resistance. We offer two primary finishes:

Titanium CarboNitride (TiCN) a.k.a. “Bronze TiN”

Titanium CarboNitride (TiCN) a.k.a. “Bronze TiN”You may have seen gold colored Titanium Nitride (TiN) before in the firearms industry. We have used it extensively in the past and it is a very good finish that has become quite popular. However, we have seen such an improvement with bronze Titanium CarboNitride (TiCN) that we now use it as our go-to barrel finish. TiCN is basically gold TiN’s lesser known, tougher cousin. TiCN is about the hardest thing out there and offers superior corrosion resistance and lubricity. We like the fact that it looks great, but it was originally chosen for its material properties. This finish is used frequently in industrial settings, in particular, on cutting tools used on very abrasive materials.

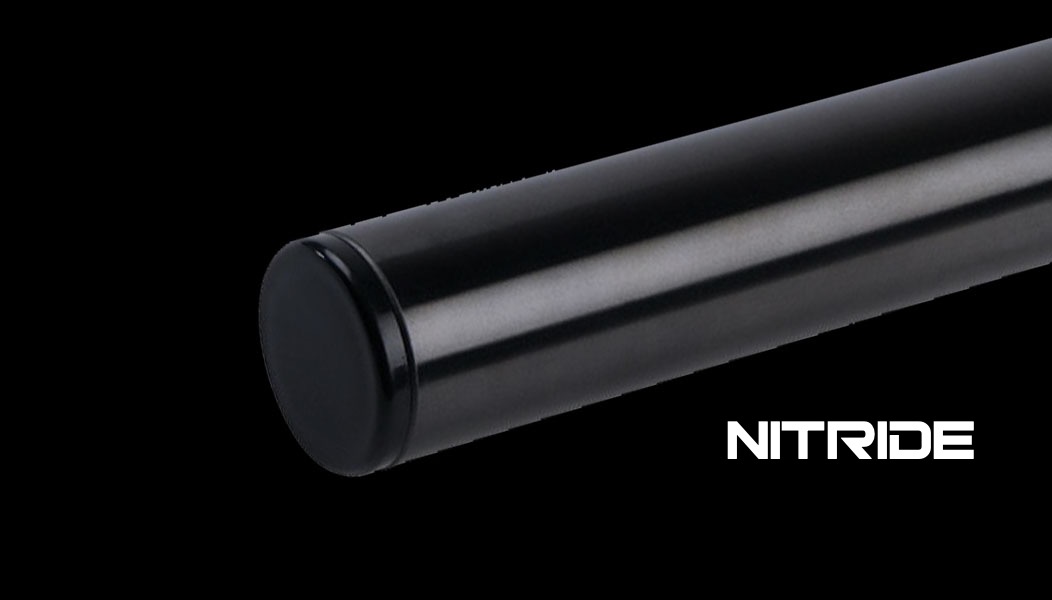

Nitride

NitrideShadow uses Nitride to finish our black components. There are many recipes and names for nitride (Tenifer, Melonite, QP, QPQ, etc. are all the same or similar). Generally, they all mean a treatment that makes the part super hard at the surface followed by a rust preventative blackening treatment. In our testing, Nitride has performed better than DLC with less wear to the finish in areas of high-contact.